More accurate flow tests, capturing actual downhole conditions, show that perforations may easily be flowing at only 30% of potential.

Scientific Background

Surging as a potent form of tertiary oil recovery has a solid basis in fact-it’s enough look at the empirical evidence of the problem and the science behind the solution to understand that.

Unsurged wells from decades of drilling have only ever flowed at a fraction of their potential, hampered by clogged perforations. Shaped charge guns perforate the formation and create tunnels that collect fluid from the formation. (See Perforation Tunnels.) The impact of the perforating guns creates a compacted zone inside the tunnel, and the shaped charge also leaves residue inside the tunnel. (See Shaped Charges.) Both effects impede flow, and the reduction of flow rate is quantifiable using lab tests that simulate realistic downhole flow conditions. (See Flow Tests.)

This observation of the problem also provides the solution: unclog the perforations and allow them to flow at full potential. Surging is a low-cost but very effective method of flushing out these perforations and optimizing flow in an existing well. (See Surging or go directly to the Results and notes about the effectiveness of surging.)

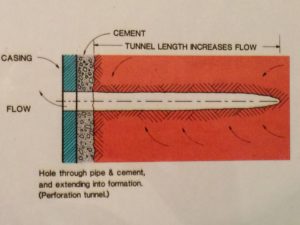

Figure 1. At well completion, shaped charges blast through casing and perforate the formation, creating tunnels that collect oil flow.

Perforations are the tunnels created by blasting through the casing and into the formation at the time of well completion. The perforation tunnels serve as the collection lines for fluid to flow into from the formation and into the tubing to the surface. They also serve as drain lines when injecting into the formation. See Figure 1.

In the 1970’s, Emmet Brieger headed a Schlumberger design group that conducted flow tests of well perforations as part of their study of well completions. They used lab simulations of down-hole conditions to observe what happens when perforations are made and flow begins. They observed two factors—residue and compaction—that both contribute to blocking or constricting flow in a producing well that has not been surged.

Flowmeter tests have indicated as many as 85% of the perforations can remain completely clogged (not flowing at all) for the lifetime of a well.

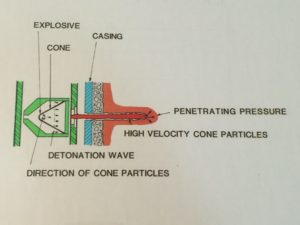

The shaped charge cone of metallic particles is contained inside the gun housing. At detonation of high explosives, a shock wave crosses the cone liner and the shaped charge particles are focused into a high-velocity jet (on the order of 20,000 ft/second) out into the formation. They penetrate the casing and cement and bombard the formation zone, pushing formation particles aside and tunneling into the formation. See Figure 2.

Figure 2. Upon detonation, a high-velocity jet of metallic particles penetrates casing and cement and tunnels into the formation by pushing formation particles aside.

Residue and Compaction – Two factors that constrict flow

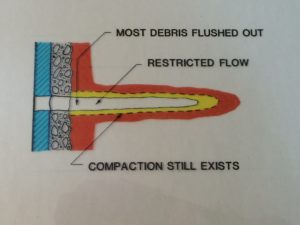

Residue: Rather than winding up with clean perforation tunnels, highly compacted shaped charge debris remains in the tunnels. A differential pressure between formation and the tubing inside the casing is required to push out this compacted residue and initiate the flow. See Figure 3.

Figure 3. Residue from the shaped charge particles remain in the tunnels after perforation; perforations may never submit enough pressure differential to flush this out and start flow.

Typical practice for putting the well on production—when it is not being surged at completion—is to gradually reduce pressure inside the tubing. This gradually sets up a pressure differential and when that attains the minimum required to start some of the tunnels flowing, the well begins producing. At that point, however, the differential pressure equilibrates, and any tunnels that were left clogged by that minimal pressure then remain clogged and have no way of ever beginning their flow.

And in fact, downhole flowmeter tests have indicated that wells can experience flow from as few as 15% of their perforations. 85% of the perforations in such wells are not flowing at all and never will unless freed of the shaped charge residue.

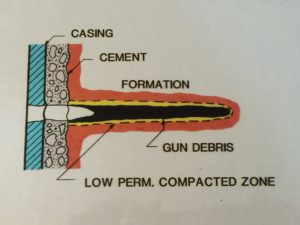

Compaction: Apart from the residue, a low-permeability compacted zone remains inside the perforation tunnel, further constricting the flow. This means that even perforation tunnels that are flowing will do so at much lower rates unless the compacted zone is cleared out. See Figure 4.

Much more accurate radial flow tests demonstrate that perforations are often flowing at only 30% of potential.

The Schlumberger group made some important observations with their flow tests—under pressure to simulate downhole conditions. Laboratory flow tests use a shaped charge to perforate a specimen that simulates the formation. Then fluid is pushed through the specimen. The rate at which it flows out of the perforation tunnel (into the “tubing”) is measured and compared against the rate of flow through an ideal tunnel drilled in an identical specimen. The comparison gives an indication of the effect of the perforation procedure on ideal flow rate.

Figure 5. Comparative linear flow tests falsely indicate almost 90% of ideal flow in perforation tunnels.

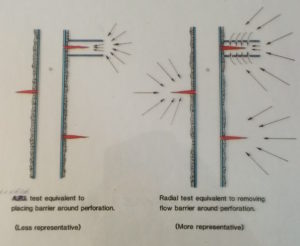

Standard lab tests are linear (and unrealistic): fluid is pushed into a linear corridor around the perforation tunnel. Flow measurements in this situation show 90% of ideal flow, seemingly indicating that shaped charge damage or blockage in perforation tunnels has little impact on flow rate. See Figure 5.

Figure 6. In situ fluid flow into the perforation tunnel comes in from all directions around the perforation.

However, in situ perforation tunnels drain fluid under pressure from the formation all along the tunnel surface, not just from the end. See Figure 6. Thus the group also set up lab tests to simulate flow from all directions. Figure 7 indicates the situation: flow through a shaped charge perforation was compared to flow in an ideal, drilled tunnel, this time allowing fluid to enter from all sides, not just from the end of the tunnel. In this case, measurements indicated perforation tunnel flow at only 30% of ideal. Both residue and compaction contribute to this effect.

Figure 7. Much more reliable radial flow tests show that perforation tunnels flow at only 30% of ideal rate.

The observations show that standard linear flow tests significantly mis-represent actual formation flow into perforation tunnels, dramatically overestimating it, and that radial flow tests are much more realistic. The tests demonstrated that it is more realistic to expect perforation tunnels to yield 30% of ideal flow rate, rather than the 90% indicated by linear tests. (Bell, Brieger, & Harrigan, 1972, Journal of Petr Tech, )

The case for surging is compelling.

- Production logs show that flow can be from fewer than 20% of the perforation tunnels, i.e. 80% of perforations simply are not flowing.

- Flow tests provide more evidence that unsurged wells easily have flow rates of only 20%-30% of their potential.

- At least 40 years worth of existing wells worldwide have never been surged.

The potential benefits are enormous.

In the 1980’s Brieger collaborated with Roy Vann at Geo Vann (now Vannsystems, a subsidiary of Halliburton). Vann’s tubing-conveyed perforation essentially surges a new completion, using a suddenly-applied differential pressure to bring in a well. The procedure is in worldwide use today because of its effectiveness at bringing in wells with high flow rates.

Brieger made the connection: surging a well can flush out much of the debris and compaction that otherwise impede flow. This is not so surprising; suddenly-applied pressure approaches twice the force of slowly-applied pressure, so the impact of surging is higher than the pressure differential alone. And the high force will be felt equally by all perforations, with greater potential to allow all of them to unclog, as opposed to what happens when gradually-applied pressure unclogs some perforations and leaves others intact (see above).

Since then, Brieger has designed and then improved various tools for surging existing wells. (See patents US4142583 A, 1979 and US4285402 A, 1981, and US 6,296,058 B1, 2001.)

In 1998 Brieger received a Department of Energy Inventions and Innovations grant (Grant DE-FG36-99GCH0446) through the DOE Office of Energy Efficiency and Renewable Energy (EERE). This grant funded a patent (US 6,296,058 B1) and the design and manufacture of one of the tools covered by the patent, along with design and manufacture of lab test equipment. The manufactured tool provides a very simple, exceedingly low risk, and even easily repeatable method for surging in consolidated formations. The final report, Wellbottom Fluid Implosion Treatment Systems, Dec 2000, is available. The interim report, Wellbottom fluid implosion system to stimulate existing well flow, Oct 1999 is available through the DOE Office of Scientific and Technical Information database.

Former high oil prices provided little incentive for service companies or operators to consider surging as a significant strategy for tertiary oil recovery; even complicated and costly EOR techniques and new completions yielded a very high ROI. As a result, awareness of the huge impact on flow rate of clogging in perforations has lagged. However, clogged perforations haven’t gone anywhere over the intervening years, and it remains the case that tens of thousands of wells in the United States are flowing at rates far below their potential simply because of clogging in the perforations.

Surging—by any method—can be observed to be greatly effective at increasing well production.

The effectiveness of surging

Tubing-conveyed perforation, which causes a formation to be surged upon completion, is now widely popular for its acknowledged high production rates, but the effect of surging on these wells is not quantifiable, since there is no before-surge flow rate data to compare with after-surge flow rates; the well is surged as it is completed.

However, in existing wells the effectiveness of surging can be studied by comparing pre-surge and post-surge flow rates. Due to general lack of awareness of the importance of surging, there are not many such comparisons, but there are some and they are significant.

Otis Engineering Corp. licensed out patent US 6,296,058 B1, manufactured the equipment, and conducted surge tests. The results exceeded all expectations. The engineers, seeing the ease with which the procedure could be repeated, treated some wells two and three times, upping production each time, as perforations were more thoroughly flushed out. Twenty-five tests were done on ten wells, though only three tests were publicly documented. These are among the tests cites below.

Results

|

| ∗ An article in World Oil, 1989, documented the effects of a single surge at 1500psi differential pressure: production was brought from 1300bpd to 1780 bpd, an increase of almost 40%. It was noted in the article: “… the method is quick and relatively inexpensive, providing good potential for early payout.” (See “Clean out existing well perforations by surging the formation,” World Oil, 1989) |

|

| ∗ An article in World Oil, 1991, reported the experience of a high-producing well in Alaska, for which the through-tubing surge treatment brought production from 2300 bpd to over 5600 bpd, an increase of 3300 bpd, almost 250% increase in production for a high-flow well. It was noted that: “This was beyond the expectations of even the most optimistic.” The surprise was not the percent increase, but this percent increase for a high-rate well. It demonstrates that the perforations were flowing at far below capacity even for that high-producing well. The article reported another well, non-producing after completion but that came into production after stimulation with the through-tubing surge device. (See “Backsurging perforations can increase production rates,” World Oil, 1991.) |

|

| ∗ In 1991-1992 a 40-well field in Trinidad—low-pressure, shallow, 30 year-old wells—was treated by surging with tubing-conveyed technology provided by Mervyn Chen. Production increase in almost all wells was at least 100%. Some non-producing wells returned to production, one well went from 60 bpd to 400 bpd production, over a 6.5-fold production increase, and one sluggish well went from producing 8 barrels per month to 97 barrels per day. (Private conversations with Mervyn Chen. Contact us for info.) |

|

| ∗ In 2006 ENI published results of a surge operation in an existing offshore well. They used a downhole air chamber to create a pressure differential and a 737 psi surge. The result was an astonishing 5-fold increase in fluid loss from the formation, compared to post-perforation losses before surging. The authors affirm that “Surging is required to maximize the productivity of perforations.” (Sanford, Woomer, Miller, & Russell, World Oil, July 2006.) |

Surging is an effective approach to well stimulation. Our surge tool also simplifies the procedure, providing uncomplicated, inexpensive, and easily repeatable surge operations.

Its time has come

In past decades, simple procedures for optimizing flow in existing wells were not nearly as enticing as complicated technologies or new completions. Large investments more than paid for themselves even at very high operations cost. However, today’s oil prices mean a negative ROI for extravagant operations, and cost-effectiveness is in much higher demand.

Well surging by any method is an effective approach to EOR in consolidated formations. It simply optimizes flow in existing wells that can easily have 70%-80% of the perforations showing no flow at all and any flowing perforations significantly constricted by the compacted zone. Surging allows perforations to begin producing at capacity.

With our tool it’s even better: the through-tubing device means easy, low-risk deployment, and pressure actuation means an uncomplicated surge operation. The re-usable tool is retrieved after an operation, so a well can be surged multiple times for thorough flushing, and no hardware is left in the well.

References

- Bell, W. T., Brieger, E. F., & Harrigan, J. W. (1972, September 1). Laboratory Flow Characteristics Of Gun Perforations. Journal of Petroleum Technology,

presentation to the Society of Petroleum Engineers. doi:10.2118/3444-PA. - Brieger, E., & Pearce, J. L. (1989, December). Clean out existing well perforations by surging the formations. World Oil, 209(6), 62+.

- Brieger, E. F. (1991, July). Backsurging perforations can increase production rates. World Oil, 212(7), 75+.

- Trinidad tests – Contact us to get in touch with Mervyn Chen.

- Emmet F. Brieger, “Wellbottom Fluid Implosion Treatment Systems”, DOE Final Report, Dec 2000, Grant DE-FG36-99GCH0446.

- Emmet F. Brieger, “Wellbottom fluid implosion system to stimulate existing well flow”, DOE Interim Report, Oct 1999, Grant DE-FG36-99GCH0446.

- Certificate of Achievement, presented by Entrepreneurs for Energy Efficiency, Inc., Meeting of the US DOE Inventions & Innovations Alumni Group, April 2002.

- Sanford, J., Woomer, J., Miller, J., & Russell, C., World Oil, Deepwater Technology: The K2 project: GOM challenges solved from a drilling engineer’s perspective, vol 227 no.7, July 2006.

- Patent US4142583 A, Well tool pack-off with sinker bar release means, 1979.

- Patent US4285402 A, Method and apparatus for stimulating oil well production, 1981.

- Patent US6296058 B1, Wellbottom fluid implosion treatment system, 2001.